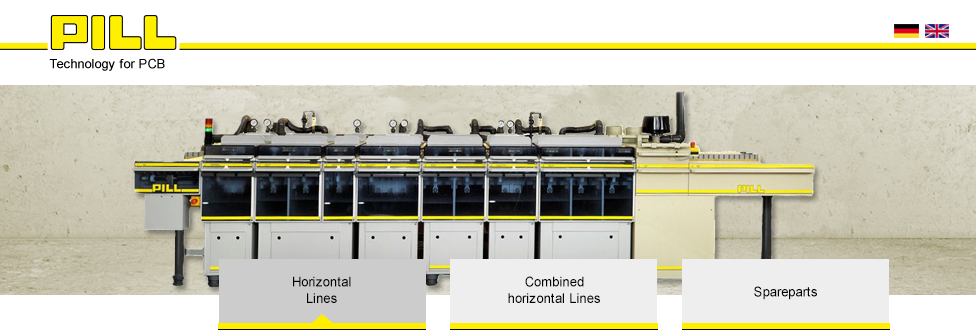

Horizontal lines

PILL systems provide you with all the equipment you need for the PCB production process. PILL was the first company in Germany to develop and successfully launch modular systems for wet chemical process lines used in PCB production onto the market. This well-established principle ensures a high degree of flexibility in the process chain and allows the simple extension and conversion of existing systems.

Our modern electronic control touch display or PC visualisation system make the systems easy and convenient to operate.

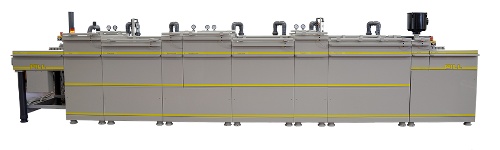

"Etching" line

Vacuum etching technology developed and patented by PILL offers a host of benefits in the PCB production process. Suction nozzles extract the etching medium from the PCBs, resulting in steeper line edges and a better etching rate.

Please feel free to contact us. We would be happy to discuss the other benefits of our systems with you.

You can find more detailed information about our patented process in our Press releases.

"Stripping" line

The PILL stripping system removes both soluble watery alkaline etch resists as well as metal etch resists and screen printing inks.

The PILL cyclone filter is a further development and enhancement of the stripping system. The filter uses a special process for separating stripped resist particles from the liquid stripper medium to prevent the nozzles from blocking, while the return of stripper solution into the storage tank makes the system extremely economical.

"Desmearing / chemical through hole plating" line

The holes on the multilayer must be cleaned before chemical through hole plating can be performed correctly. The through holes are then chemically copper plated. The PILL desmearing and chemical through hole plating systems optimise these working procedures perfectly for further processing.

"Direct metallisation" line

The PILL direct metallisation system can perform all the most common techniques such as BlackHole HT, Shadow, Envision HDI and many more. We would be happy to discuss the various advantages and disadvantages of the different techniques with you. Do not hesitate to contact us!